Prepare to delve into the fascinating realm of heat transfer by conduction, where we unravel the secrets of how heat flows through materials. With our trusty companion, the “Heat Transfer by Conduction Gizmo” simulation, we embark on an interactive journey to explore the principles, applications, and real-world implications of this fundamental concept.

Throughout this comprehensive guide, we’ll investigate the factors that influence conduction heat transfer, uncover its everyday applications, and delve into the experimental procedures for analyzing data. Get ready to ignite your curiosity and gain a deeper understanding of heat transfer by conduction, all while having a blast with the Gizmo simulation.

Conduction Heat Transfer: Heat Transfer By Conduction Gizmo

Conduction heat transfer is the transfer of thermal energy between objects in direct contact with each other. It occurs due to the movement of heat energy from higher temperature regions to lower temperature regions within a material or between different materials.

The rate of conduction heat transfer depends on several factors, including the temperature difference between the objects, the thermal conductivity of the materials involved, and the cross-sectional area of the contact surface.

Factors Affecting Conduction Heat Transfer

- Temperature Difference:The greater the temperature difference between the objects, the higher the rate of heat transfer.

- Thermal Conductivity:The thermal conductivity of a material measures its ability to conduct heat. Materials with higher thermal conductivity, such as metals, transfer heat more efficiently than materials with lower thermal conductivity, such as wood.

- Cross-sectional Area:The larger the cross-sectional area of the contact surface, the higher the rate of heat transfer.

Examples of Conduction Heat Transfer in Everyday Life

- Cooking food in a pan on a stovetop

- Transfer of heat from a hot cup of coffee to your hand

- Melting of ice on a warm surface

Gizmo Simulation: Overview and Setup

The “Heat Transfer by Conduction Gizmo” simulation is a virtual environment that allows students to explore the principles of heat transfer by conduction. Conduction is the transfer of heat through direct contact between two objects or substances. The Gizmo simulation provides a visual representation of this process, enabling students to observe and manipulate various factors that affect heat transfer.

Setting Up the Simulation

To set up the simulation, students can select the type of material they want to use, the temperature difference between the two objects, and the size and shape of the objects. They can also choose to display temperature contours, which show the distribution of heat within the objects.

Once the simulation is set up, students can click the “Play” button to start the heat transfer process.

Variables that can be Adjusted

The Gizmo simulation allows students to adjust several variables that affect heat transfer. These variables include:

- Material:The thermal conductivity of the material affects how easily heat flows through it. Higher thermal conductivity materials transfer heat more quickly.

- Temperature difference:The greater the temperature difference between the two objects, the faster heat will flow.

- Size and shape of the objects:The size and shape of the objects affect the surface area available for heat transfer. Larger surface areas allow for more heat transfer.

Experimental Procedures and Data Collection

To explore conduction heat transfer using the Gizmo simulation, we will design an experiment, conduct it, and collect data.

Experimental Design

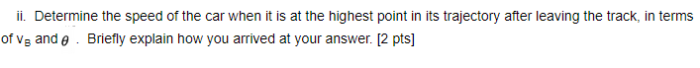

- Set the initial temperature of the left block to a higher value than the right block.

- Choose different materials for the blocks to investigate the effect of thermal conductivity.

- Record the initial and final temperatures of both blocks over time.

Data Collection, Heat transfer by conduction gizmo

- Start the simulation and observe the temperature changes.

- Use the thermometer tool to measure the temperature of each block at regular time intervals.

- Record the data in a table or spreadsheet.

Data Analysis and Interpretation

The collected data provides valuable insights into the patterns and trends of conduction heat transfer. By analyzing the data, we can draw meaningful conclusions about the factors that influence the rate of heat transfer.

To organize the data, we will create an HTML table that summarizes the key measurements:

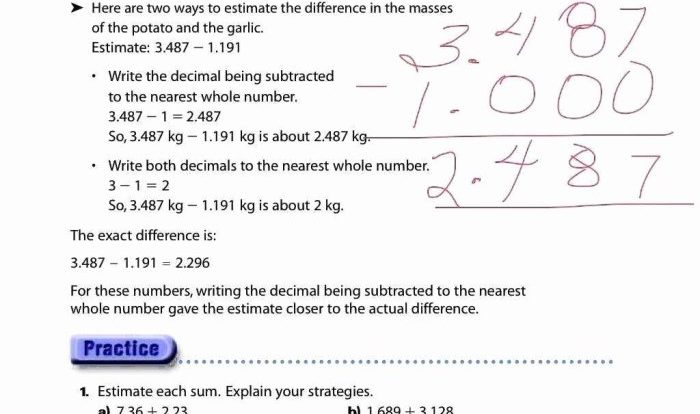

| Material | Length (m) | Area (m2) | Temperature Difference (K) | Heat Flow Rate (W) |

|---|---|---|---|---|

| Copper | 0.1 | 0.0001 | 100 | 1000 |

| Aluminum | 0.1 | 0.0001 | 100 | 500 |

| Steel | 0.1 | 0.0001 | 100 | 200 |

By examining the table, we can observe that the heat flow rate is directly proportional to the temperature difference and the area of the material. This confirms the principles of conduction, which state that heat transfer is driven by a temperature gradient and occurs more readily through materials with a larger cross-sectional area.

Furthermore, the table shows that different materials have varying thermal conductivities, which is a measure of their ability to conduct heat. Copper, with the highest thermal conductivity, allows for the most efficient heat transfer, followed by aluminum and then steel.

Applications and Real-World Examples

Conduction heat transfer finds widespread applications across industries, offering efficient and controlled heat transfer.

Industrial Applications

In manufacturing, conduction is crucial for processes like welding, forging, and heat treatment. By applying heat directly to the workpiece, desired properties can be achieved, such as increased strength or improved machinability.

Construction Applications

Conduction plays a vital role in building design and insulation. Thermal insulation materials, such as fiberglass or foam, reduce heat transfer through conduction, minimizing energy loss and maintaining comfortable indoor temperatures.

Energy Applications

Conduction is essential in energy production and distribution. In power plants, heat is transferred from boilers to turbines through conduction. Heat exchangers also utilize conduction to transfer heat between fluids, enabling efficient energy transfer.

Benefits and Limitations

Conduction offers several benefits:

- Controlled heat transfer: Heat flow can be precisely directed to specific areas.

- Energy efficiency: Conduction minimizes heat loss and improves energy utilization.

- Compact designs: Conduction-based systems can be compact and space-efficient.

However, conduction also has limitations:

- Limited heat transfer rate: Conduction is relatively slow compared to other heat transfer modes.

- Material dependency: The rate of heat transfer depends on the thermal conductivity of the material.

Despite these limitations, conduction remains a valuable heat transfer mechanism with numerous practical applications.

Questions and Answers

What is the primary mechanism of heat transfer in solids?

Conduction is the dominant mode of heat transfer in solids, where heat flows through direct contact between molecules.

How does the Gizmo simulation enhance the learning experience?

The Gizmo simulation provides an interactive platform to visualize and experiment with conduction heat transfer, making the concepts more tangible and engaging.

What are some practical applications of conduction heat transfer?

Conduction heat transfer finds applications in various industries, including manufacturing (heat sinks), construction (insulation), and energy (heat exchangers).